The Ultimate Source for Learning Litho Printing and Its Applications

In the globe of print innovation, litho printing holds a substantial place as a result of its versatile applications and top quality outcomes. This comprehensive overview covers every facet of grasping litho printing. It explores the core principles, elucidates on innovative strategies, discovers the necessary devices, and provides sensible remedies for typical problems. As the conversation proceeds, you'll discover just how litho printing is forming sectors such as posting, marketing, and electronic devices. Keep tuned to discover the interesting intricacies of this impressive printing method.

Comprehending the Essentials of Litho Printing

Litho printing, an artform with roots expanding back to the late 18th century, is a complex and intricate process needing both technological ability and artistic skill. This conventional method of printing relies on the concept that water and oil do not mix. This fundamental understanding lays the structure for further expedition into litho printing's intricacies.

The Scientific research Behind Lithography: A Deep Dive

While the standard procedure of litho printing provides it its special beauty, an extra profound understanding lies in the complex interaction of chemistry and physics at job. Lithography, at its core, rests on the concept that oil and water do not blend. The photo is attracted with a hydrophobic, or water-repelling, material onto a level lithographic sedimentary rock plate. The non-image locations, hydrophilic in nature, maintain water. When home plate is tattooed, the hydrophobic picture regions attract the oily ink while the wet, non-image areas repel it. This selective destination and repulsion create the preferred photo on the plate. The plate is then pressed against a sheet of paper, transferring the tattooed picture with amazing accuracy and information. The scientific research of lithography is without a doubt a wonder.

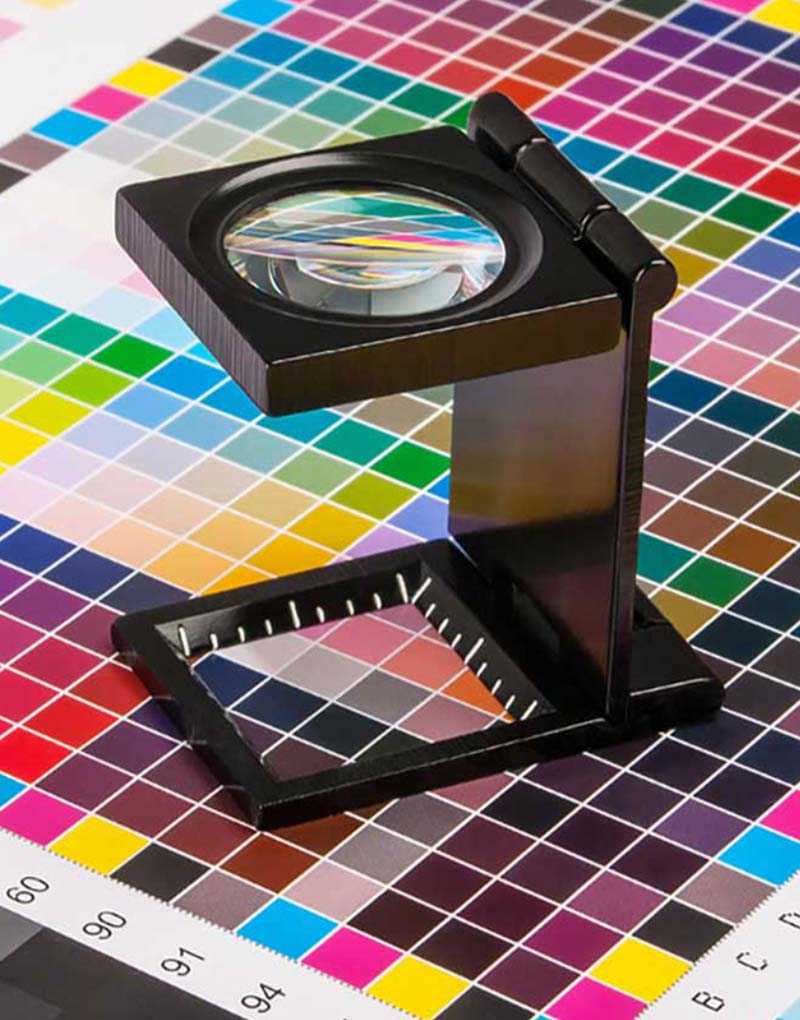

Devices and Materials Needed for Effective Litho Printing

To begin on the journey of litho printing, one should first collect the vital equipment and products. This consists of a lithographic press, an essential piece of equipment that applies pressure to move the photo onto the medium. Next off, lithographic stones or top quality lithographic light weight aluminum plates are important, as these are where pictures are attracted or engraved. Additionally, lithographic pastels or pencils, tusche, and chemical options like periodontal arabic, acid, and turpentine are required for picture creation and handling. Lastly, inks and premium paper or other media to publish on are crucial. Each component plays a special role, adding to the top quality and performance of the last litho print. Adequate preparation with the right products ensures a smoother printing procedure.

Advanced Techniques in Litho Printing: A Step-By-Step Guide

Recognizing Litho Printing Essentials

In the realm of print production, litho printing stands as a prominent technique that incorporates art and technology. The term 'lithography' stems from the Greek words 'lithos' meaning stone and 'graphein' to create. The process depends on the immiscibility of oil and water, where an image is put on a grained surface area with a greasy medium. A chemical service is after that used to deal with the surface area, enabling just the oily areas to accept ink. Next, a blanket cyndrical tube gets the inked photo and lastly transfers it onto a paper, producing a mirror-image print. Litho printing is preferred as a result of its top quality, cost-effectiveness for large runs, and compatibility with a large range of printing surfaces.

Improving Litho Publish Outcomes

Real-World Applications of Litho Printing in Modern Technology

The range of litho printing is not confined to a musician's canvas, however expands its impact into contemporary technology. Its applications penetrate industries such as publishing and business, where high volume printing needs are ubiquitous. Even in the world of electronic devices, litho printing has discovered considerable usage, changing standard production processes.

Litho Printing in Posting

Litho printing, a mainstay in the posting sector, showcases its performance through modern-day innovation applications. Litho printing is cost-efficient for huge runs, an important factor in the financially tight publishing discover this info here market. Its regular high quality and affordable benefits solidify litho printing's location in the heart of posting.

Commercial Litho Printing Makes Use Of

Building on its prestige in the publishing industry, litho printing likewise discovers substantial application in the broader commercial field. Litho printing ensures the production of distinctive and resilient prints, promoting brand name presence and item allure. Litho printing is utilized in label production, where the demand for vivid, high-resolution prints is high.

Litho Printing in Electronic Devices

Remarkably, litho printing has actually located its way into the world of electronics, showing its flexibility and importance in the modern-day globe. It is currently thoroughly made use of in the manufacture of electronic elements such as published circuit boards (PCBs) The process involves transferring a photo onto a steel plate, which is then etched to create a stencil. This stencil is used to print elaborate circuit patterns onto a substrate with severe accuracy - litho printing. Litho printing additionally provides the advantage of high-volume production at a reduced price, making it ideal for electronic devices making. For this reason, it has actually ended up being an indispensable component of the electronic market, demonstrating exactly how this traditional printing approach continues to progress and locate brand-new applications.

Simple Troubleshooting Tips for Typical Litho Printing Issues

Also seasoned printmakers sometimes come across problems with litho printing. Common troubles consist of poor image high quality, plate wear, and ink misbehavior. Understanding these issues can help boost and fix printing results.

Photo quality problems frequently emerge from inaccurate exposure times, bring about overdeveloped or incomplete photos. Remedying direct exposure times can address this problem. litho printing. Plate wear, brought on by extended exposure to stress and rubbing, can cause uneven print top quality. Routine plate maintenance and substitute can reduce this concern.

Ink misdeed, such as smudging or inconsistent colors, can happen due to inappropriate ink uniformity or wrong temperature level setups. Ensuring the correct ink uniformity and keeping optimal temperature level conditions can help handle these problems. Fixing litho printing problems requires careful monitoring, understanding of procedure ins and outs, and quick, informed action.

Final thought

To conclude, The Ultimate Resource for Learning Litho Printing and Its Applications acts as a crucial guide, supplying in-depth knowledge on the intricacies of litho printing. With its emphasis on the underlying science, needed tools, progressed methods, and real-world applications, it really encourages both novices and seasoned experts. Its sensible troubleshooting tips offer important support in conquering usual concerns, further enhancing print top quality and effectiveness.

In the world of print modern technology, litho printing holds a substantial location due to its high-grade outcomes and flexible check these guys out applications.Having mastered the basics of litho printing and acquainted oneself with the required devices and materials, the trip in the direction of honing sophisticated litho printing skills now beckons.In the world of print manufacturing, litho printing stands as a noticeable method that integrates art and technology. Litho printing is favored due to its high quality, cost-effectiveness for big runs, and compatibility with a large range of printing surfaces.

In final thought, The Ultimate Resource for Mastering Litho Printing and Its Applications offers as a vital overview, supplying thorough understanding on the complexities of litho printing.